How To Solve Problems Of Stainlesse Steel Electronic Scales In Special Environments And Do Daily Maintenance

Release Time:

Oct 02,2025

As a leading manufacturer of precision weighing equipment, we often hear a common assumption: "It's stainless steel, so it can't rust, right?" While stainless steel is an incredibly robust material, its invincibility is a myth, especially when it's pushed to the limit in harsh industrial environments. The difference between a scale that lasts for a decade and one that fails in a year often comes down to understanding the specific challenges of your environment and implementing the right preventive maintenance.

Today, we're moving beyond the spec sheet to look at real-world failures and their solutions. Drawing from our direct experience with clients in the seafood and meat processing industries, we will analyze why even high-quality stainless steel scales can fail and provide a comprehensive guide to ensure the longevity and accuracy of your investment.

Failure Analysis—A Deep Dive into Why Scales Fail Before we can find a solution, we must accurately diagnose the problem. The issues affecting a scale in a saline seafood plant are different from those in a high-washdown meat facility. Here’s a breakdown of the most common culprits we encounter.

Chloride-Induced Pitting & Crevice Corrosion This is the primary enemy in any environment with high salt content, like a seafood processing factory. Standard Grade 304 stainless steel, while excellent for general purposes, is susceptible to chlorides (the 'Cl' in NaCl, or salt). Seawater and brine break down the passive, protective chromium oxide layer on the steel's surface. This doesn't cause uniform rusting like on regular steel; instead, it creates tiny, deep, localized "pits" that can compromise structural integrity. Crevice corrosion is similar, occurring in tight gaps like those under bolt heads or between overlapping plates where stagnant, salty moisture gets trapped.

Galvanic Attack This electrochemical reaction occurs when two different metals are in contact in the presence of an electrolyte (like salty water). For example, if a mild-steel bolt is used to attach a component to a stainless steel frame, the less noble metal (the bolt) will rapidly corrode, acting as a sacrificial anode to protect the stainless steel. This can lead to the failure of fasteners and compromise the entire assembly.

Chemical Incompatibility with Detergents In washdown environments like meat and poultry plants, daily sanitation is non-negotiable. However, the aggressive sanitizers and detergents used often contain their own chlorides or other chemicals that are hostile to stainless steel. If not properly rinsed, these cleaning agents can linger on the surface and degrade the passive layer, leading to corrosion that is often mistaken for simple water damage.

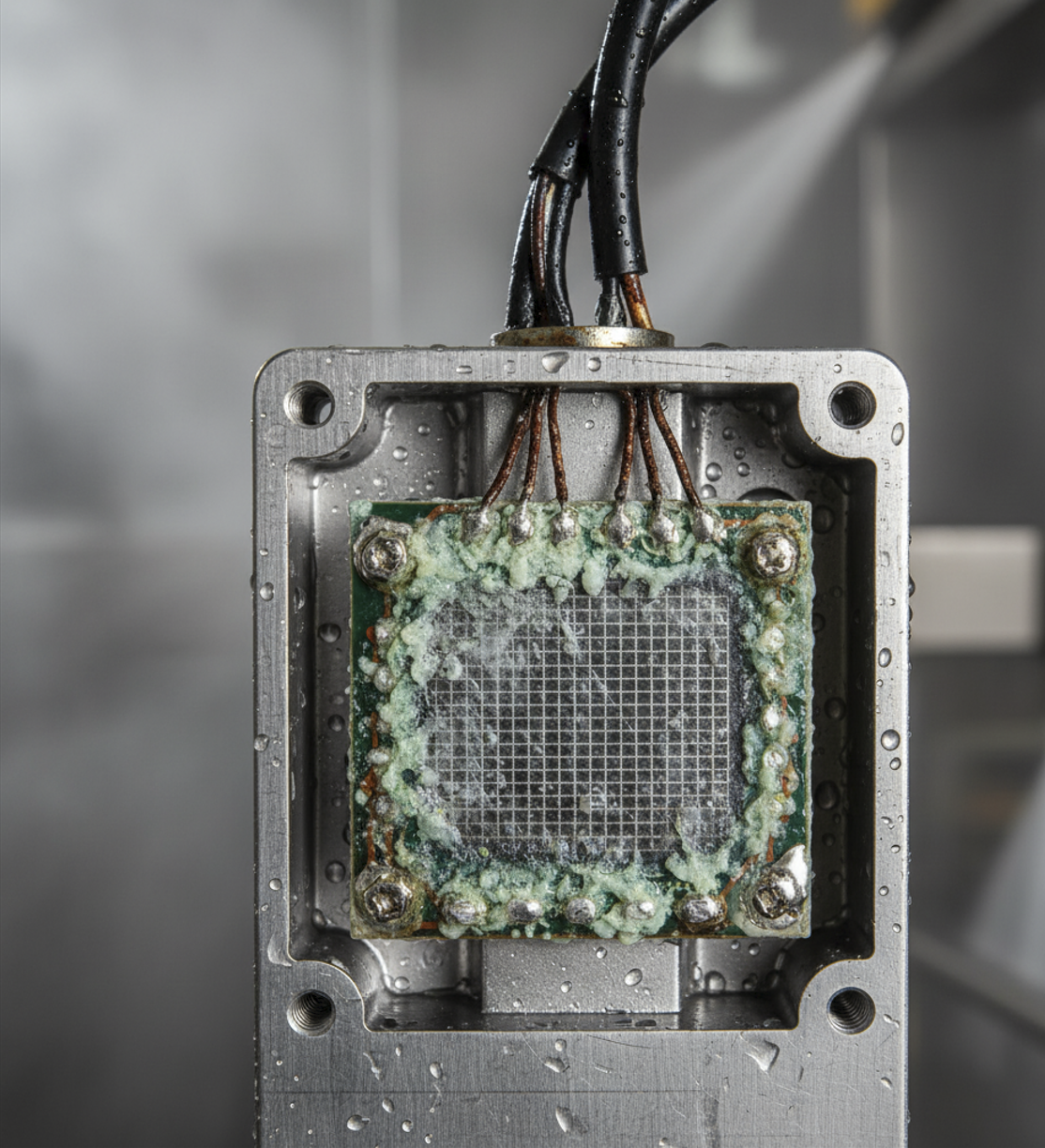

Water Ingress into Junction Boxes & Load Cells This is the most frequent point of electronic failure we see in high-washdown environments. A client at a meat processing facility was experiencing constant scale malfunctions. Upon inspection, we found their junction boxes were full of condensation and foggy residue. High-pressure water jets, used for daily cleaning, are exceptionally good at finding the weakest point in a seal. Water forces its way past poorly-seated gaskets or improperly tightened cable glands, shorting out the sensitive electronics within the junction box and even wicking down cables into the load cells themselves.

Condensation from Thermal Cycling This is a more subtle, but equally destructive, issue. A scale operating in a refrigerated room is washed down with hot water. This rapid temperature change (thermal cycling) causes the air trapped inside the junction box or other enclosures to expand and contract. As the unit cools back down, it draws in warm, moist ambient air. When this humid air hits the cold internal surfaces, it condenses—forming liquid water inside the supposedly sealed electronics, leading to drift, errors, and eventual failure.

Solutions and Preventive Measures—Your Action Plan Understanding the failure modes is half the battle. Now, let’s focus on the proactive engineering controls and maintenance protocols you can implement to protect your equipment.

Material Upgrades: 316L/Duplex and Passivation For environments with high chloride exposure (seafood, brine), upgrading from Grade 304 to Grade 316L stainless steel is the first line of defense. The addition of molybdenum to the alloy dramatically increases its resistance to pitting and crevice corrosion. For the most extreme applications, Duplex stainless steels offer even greater strength and corrosion resistance. Passivation, a chemical process that thickens and strengthens the steel's protective layer after fabrication, should be considered a standard requirement for scales in these environments.

Hermetically Sealed Components (IP68/IP69K) For electronics, sealing is everything. A scale for a washdown area must utilize hermetically sealed, IP68 or IP69K-rated load cells.

IP68 ensures the component can survive continuous submersion in water. IP69K is the gold standard for washdown, certifying that the component can withstand high-pressure, high-temperature water jets. Insisting on this rating for your load cells is non-negotiable. Properly Sealed Junction Boxes and Cable Glands An IP-rated box is useless if installed incorrectly. Ensure that liquid-tight, corrosion-resistant cable glands are used for all cable entries. It is critical that they are the correct size for the cable and are tightened to the manufacturer’s specification to create a perfect seal without damaging the cable jacket. The junction box lid gasket must be clean, correctly seated, and undamaged before closing.

Controlled Washdown Protocols & Drainage Design Train your sanitation crew. While the scale should be built to withstand washdowns, best practices can significantly extend its life. Avoid spraying high-pressure jets directly at the display indicator, the junction box seams, or where cables enter the frame. When designing the installation, ensure the scale has proper drainage. Weep holes can be drilled in non-structural, non-sealed parts of the frame to prevent water from pooling. For enclosures, a breather vent (which allows air pressure to equalize while blocking water molecules) can be a game-changer in preventing condensation buildup from thermal cycling.

Routine Inspections and Drying Maintenance is an active process. Implement a simple weekly or monthly checklist:

Visual Inspection: Look for any early signs of pitting or rust-colored stains, especially around welds and fasteners. Seal Check: Examine cable glands and enclosure seals for any signs of damage or degradation. Internal Inspection: During a planned shutdown in a dry state, briefly open the junction box cover. Is there any sign of moisture, fogging, or a white/green residue on the terminals? Dry Down: After cleaning, use compressed air or a cloth to dry the scale, paying attention to areas where water can collect. For enclosed electronics, placing a desiccant pack inside the junction box is a low-cost, highly effective way to absorb any ambient moisture that gets in. Conclusion: A Partnership for Performance Protecting your stainless steel scale in a challenging environment is a partnership between procuring the right equipment and implementing the right procedures. A scale is not just a piece of metal; it’s a precision instrument. By understanding the specific threats in your facility—be it salt or sanitation—and applying these solutions, you can ensure your weighing equipment remains accurate, reliable, and productive for years to come.

If you are facing unique challenges or are unsure which solution is right for your application, don't hesitate. Contact our experts today. We don't just sell scales; we provide robust weighing solutions engineered for the reality of your operations.

Related News