What Stainless Steel Is—and Why It Can Still Rust?

Release Time:

Sep 28,2025

What Stainless Steel Is—and Why It Can Still Rust?

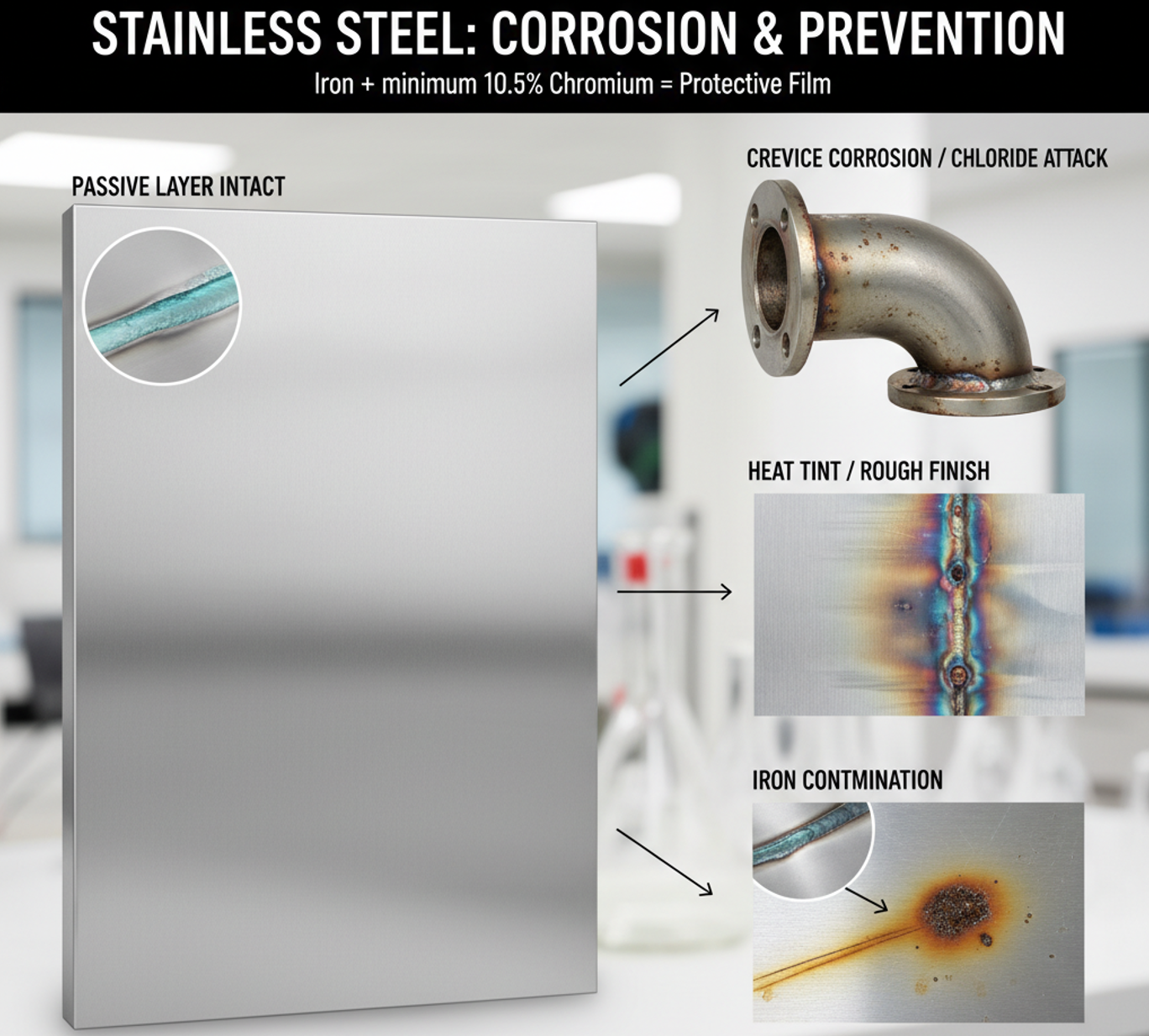

Customers expect “stainless” scales to stay spotless. Rust spots trigger complaints and lost trust. The fix: understand grades, fabrication, and environments—then choose wisely and care correctly. snippet paragraph: Stainless steel is iron with at least 10.5% chromium that forms a protective, self-healing film. It can still rust when chlorides, crevices, heat tint, rough finishes, or iron contamination damage that film. Correct grade selection, fabrication, and maintenance keep the passive layer intact. [image placeholder] Transition Paragraph: If you’ve ever seen brown marks on “stainless,” you’re not alone. We even had a coastal seafood client whose scale stained from seawater. Stay with me: we’ll map grades to environments, fix fabrication mistakes, and adopt simple care routines that prevent rust—and customer complaints—before they start.

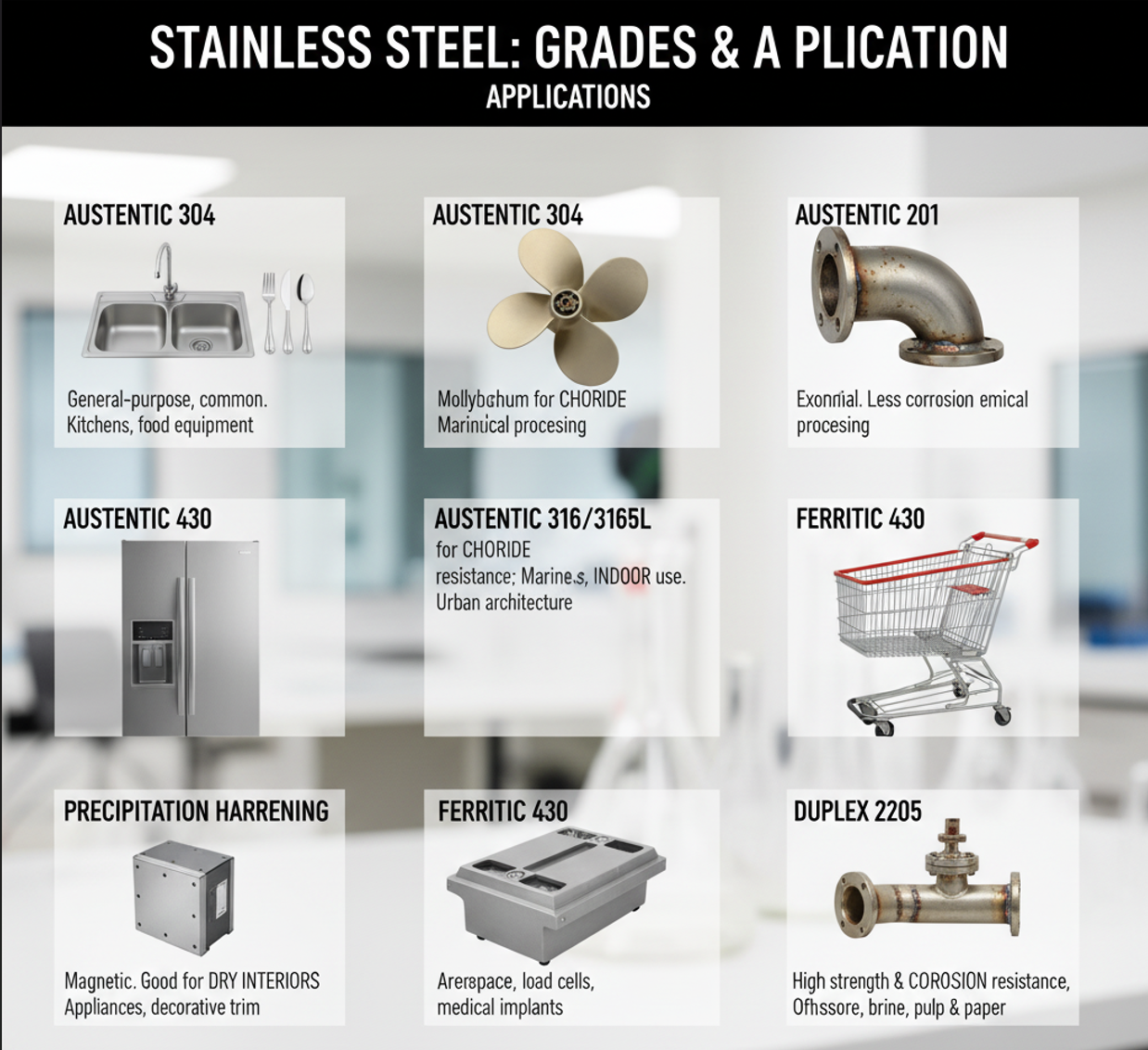

Types and Grades at a Glance?

Pick the wrong stainless and you buy headaches. Mis-matched grades stain, pit, and tarnish reputations. The solution: know the families and use cases at a glance. snippet paragraph: Austenitic 304 is general-purpose; 316/316L adds molybdenum for chloride resistance; 201 is economical but stains faster; 430 suits dry interiors; 17‑4PH brings strength for load cells; duplex 2205 resists brine. Choose by environment, hygiene demands, strength, and budget—not by name alone. [image placeholder] Dive deeper Paragraph:

Stainless families at a glance

| Grade | Family | Corrosion resistance | Strength | Typical scale uses | Notes |

|---|---|---|---|---|---|

| 201 | Austenitic | Low–medium | Medium | Indoor frames, covers | Avoid chlorides and bleach |

| 304 | Austenitic | Medium | Medium | Platforms, enclosures | Good all-rounder; needs drainage |

| 316/316L | Austenitic | High (chlorides) | Medium | Washdown, food/pharma | L version reduces weld sensitization |

| 430 | Ferritic | Low | Medium | Dry interior trim | Magnetic; economical |

| 17‑4PH | PH hardened | Medium (needs passivation) | High | Load cells, shafts | Heat-treat for properties |

| 2205 | Duplex | Very high | High | Coastal/chemical frames | Excellent in brine |

- Prioritize 316L for salt, seafood, or routine washdowns.

- Use 304 where cleaning is regular and water drains quickly.

- Keep 201 for dry, non-chloride areas only.

- Passivate 17‑4PH and any machined parts.

- Consider duplex 2205 when coastal complaints are costly.

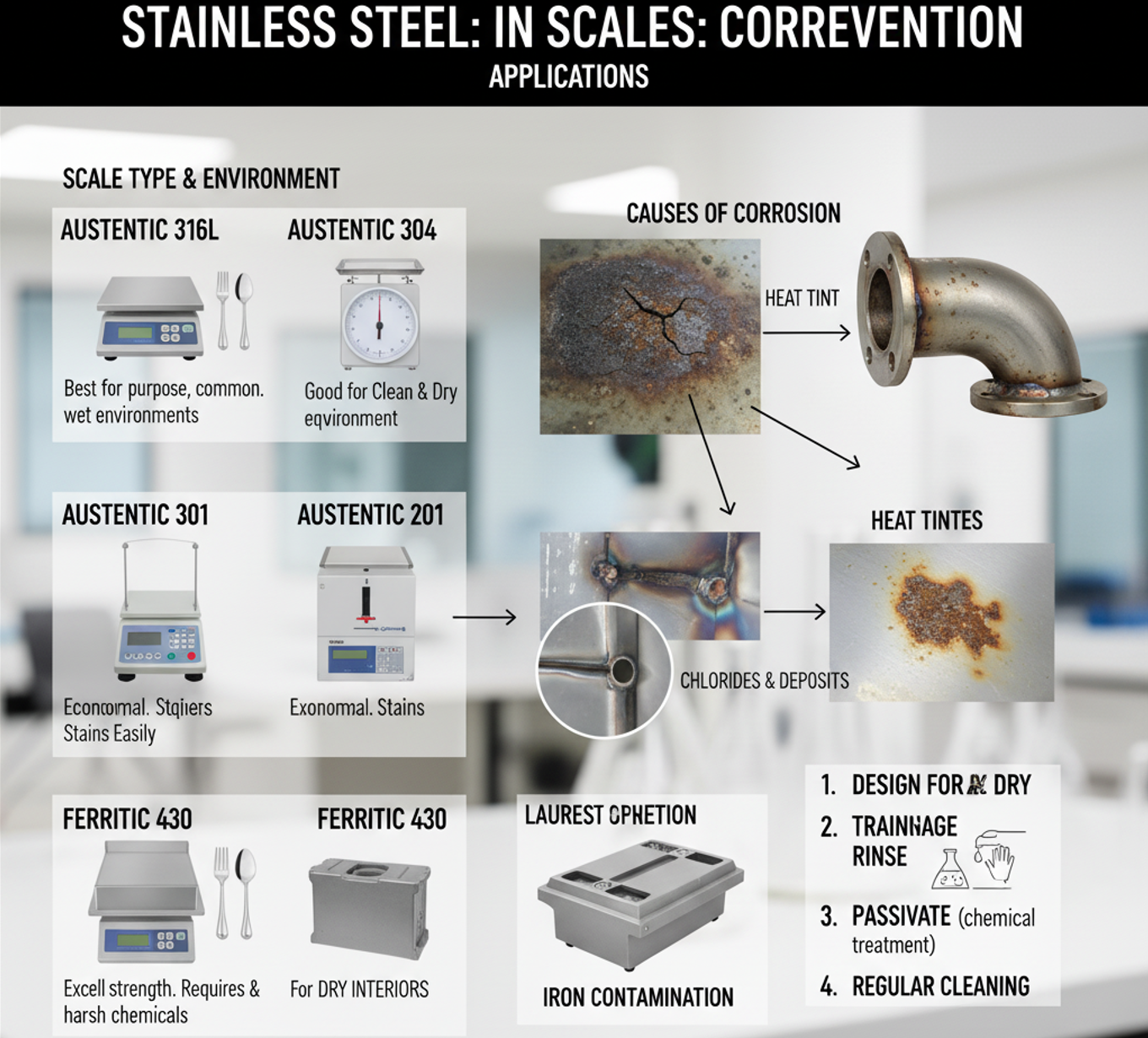

Stainless Steel for Industrial Scales: Types, Real-World Rust Behavior, and Care?

Theory says stainless resists corrosion; reality shows tea staining after washdowns and coastal shifts. Bridge the gap with grade choice, smart design, and simple, repeatable care. snippet paragraph: In scales, 316L best handles chlorides; 304 performs when kept clean and dry; 201 stains fastest; 430 is for dry interiors; 17‑4PH needs passivation; duplex excels in brine. Rust arises from chlorides, deposits, crevices, heat tint, and contamination. Design for drainage, rinse, dry, and passivate. [image placeholder] Dive deeper Paragraph:

Field scenarios and actions

| Scenario | Rust risk | Best grade | Key protections |

|---|---|---|---|

| Coastal seafood, salt spray | High tea staining/pitting | 316L or 2205 | Fresh-water rinse, frequent drying, electropolish |

| Routine washdown (alkaline) | Medium | 316L | Smooth finishes, thorough rinse and dry |

| Bleach/hypochlorite nearby | High | 316L (avoid) | Replace with neutral detergents; immediate rinse |

| Standing water/poor drainage | High | 316L | Redesign to shed water; remove gaskets trapping liquid |

| As-welded surfaces with heat tint | High | 304/316L | Pickle and passivate before service |

| We once helped a coastal seafood client whose 304 platform stained quickly. Switching to 316L, electropolishing, and enforcing fresh-water rinses after each shift cut complaints to zero. |

Care that sticks

- Clean deposits under mats, labels, and corners—crevices starve oxygen.

- Use citric passivation after repairs; verify with a water-break test.

- Segregate tools to prevent iron contamination (no carbon-steel brushes).

Environment, Processing, and Maintenance: Keeping Scales Rust-Free Longer?

Even premium stainless fails without the right environment and care. Chlorides, poor drainage, and rough welds invite rust. The fix: control exposure, process correctly, and maintain on a simple schedule. snippet paragraph: Specify 316L for washdown; pickle and passivate welds; avoid iron contamination; choose smooth or electropolished finishes; design for drainage; rinse with fresh water and dry; inspect crevices and gaskets; use neutral detergents. These practices keep the passive film healthy and scales rust-free far longer. [image placeholder] Dive deeper Paragraph:

Practical maintenance schedule

| Task | Frequency | Why it matters | How to do it well |

|---|---|---|---|

| Fresh-water rinse after cleaning | Every wash | Removes chlorides and deposits | Low-pressure rinse; avoid salt-laden water |

| Thorough drying (welds/fasteners) | Every wash | Stops crevice corrosion | Air blow or microfiber; eliminate pooling |

| Neutral/mild-alkaline detergents | Routine | Protects passive film | No bleach or HCl; soft brushes only |

| Inspect crevices, gaskets, labels | Weekly | Finds trapped contaminants | Lift, clean, re-seat for drainage |

| Passivation (citric preferred) | Quarterly | Restores passive layer | Clean, apply per spec, rinse, dry |

| Tooling segregation (no carbon steel) | Ongoing | Prevents iron contamination | Dedicated stainless tools and benches |

Fabrication essentials

- Pickle and passivate welds; remove heat tint before service.

- Use low-carbon fillers for 316L; avoid sensitization.

- Design to shed water—no horizontal ledges or tight crevices.

- Isolate dissimilar metals with polymer washers and gaskets.

- Prefer fine-brushed or electropolished finishes in hygiene or coastal sites.

Related News